Industrial facilities depend on pumps to keep fluids flowing through pipe lines. One basic type of pump is a positive displacement pump. There are many different types of positive displacement pumps which move fluids in different ways. To keep the positive displacement pumps in your facility working properly, you need to have a basic understanding of how they operate and how to maintain them. Positive displacement pumps can be divided into two groups: reciprocating pumps and rotary pumps.

Reciprocating Pumps

This common type of positive displacement pump uses the back and fort of reciprocating movement of a piston, plunger or diaphragm to move fluid. The reciprocating pumps are able to handle abrasive and viscous fluids, due to their low-speed. They do not require lots of horsepower to be highly efficient. This makes reciprocating pumps ideal for high-pressure applications. Reciprocating pumps have disadvantages as well. They require higher initial and maintenance costs compared to rotary and centrifugal pumps.

Piston Pump

The most common type of reciprocating pump is the piston pump. Its main components are a cylinder, which is located inside the casing, a piston, a connecting rod and two valves. The connecting rod connects the piston to devices that move the piston back and forth. When the piston moves back it reduces the pressure inside the cylinder. The reduced pressure closes the discharge valve opens the suction valve and draws fluid into the cylinder. When the piston moves forward, it exerts the force on the fluid that increases the pressure. The increased pressure closes the suction valve, opens the discharge valve and pushes the fluid out of the pump.

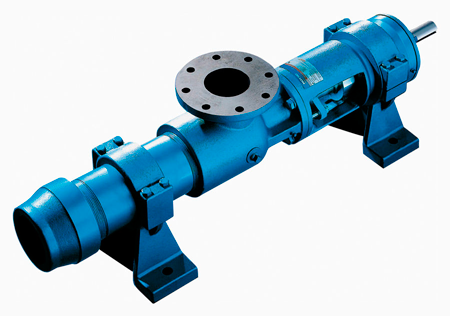

Rotary Pumps

Rotary pumps are also very common, but are designed for fluids with high viscosity and small flow rate. They are most commonly used for moving lube oils through turbines, engines, process-machinery bearings and reduction gears using the principles of rotation. Positive displacement rotary pumps remove air from the lines and eliminate the need for bleeding the air manually. They can be divided in three main types: external and internal gear pumps, lobe pumps and vane pumps.

Gear Pump

The most common type of rotary positive displacement pump is the gear pump. It is designed for pumping fluids with high viscosity. Whether an external or internal, a gear pump creates a void and suction to be filled with fluid, which is further carried by gears to the discharge section of the pump.

Lobe Pump

A type of pump that is similar to gear pump is the lobe pump. This lobe pump has two rotors and each rotor has two lobes that move fluid through the pump. Depending on the design, the lobe pump can have two, three or four lobes on each rotor.