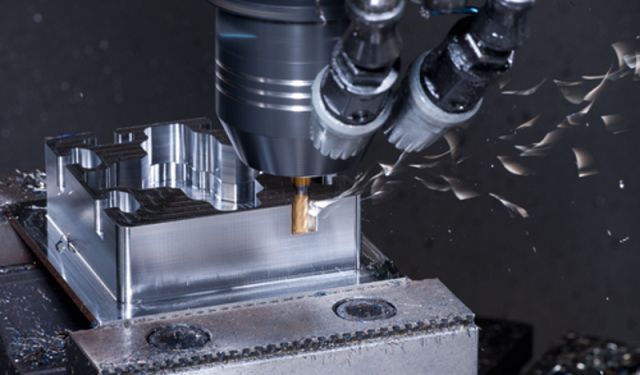

We are all aware of the devastating effects wars can have, however technology would not have advanced so greatly (or at least not this fast) had it not been for groundbreaking designs during such difficult times. From rotary filling to milling, a lot of persistence and shrewdness was required to invent something that would be better than enemy machinery and outsmart them. It was during WWII that CNC machining was brought to use.

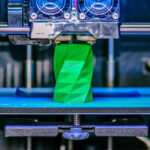

CNC, which stands for Computerised Numerical Control, is the process of creating a design through CAD (Computer Aided Design) software that a computer converts into numbers. The first CNC machining was used for more precision with creating aircraft. Of course this type of production has gone a long way since the prototype of CNC. The base of CNC milling is comprised of tools required for cutting and shaping metal and other solid materials. While in the past the system of the machine had to be operated manually, a lot of time is saved nowadays thanks to the automated mechanism. Industrial production has undergone considerable changes.

Because of the countless advantages, all sorts of industries make use of this computerised system and there are many CNC milling machines to choose. From aerospace, agriculture, automotive, electronics and military to medical industry, there certainly is not a branch that has not benefited from CNC milling. The specialised design makes it perfect for accurate shaping of aircraft structures, plane and car engine parts, transmission housing, many kinds of TV and mobile phone parts, as well as firearm components. It is especially of crucial importance for medicine because many surgeries that were previously deemed impossible or risky have been simplified significantly. A large number of surgical tools are produced by CNC machines, and most of the orthopaedic implants such as prosthetic knees and hips, even including spinal implants.

Along with fabrication of complex products, these machines can find their way in homes in a like manner since they are also fit for short-run production and any ideas for when your creativity strikes. They differ from the other machines in their size as they are designed compactly to adequately not take up much space and can easily be your next desk accessory. From home use to large scale industry manufacturing, CNC milling probes into endless aspects. Though prices of these machines may be slightly higher than manually operated ones, it is an investment worth considering as it will pay off eventually. Recently there are many new models emerging which results in a drop of the price range.