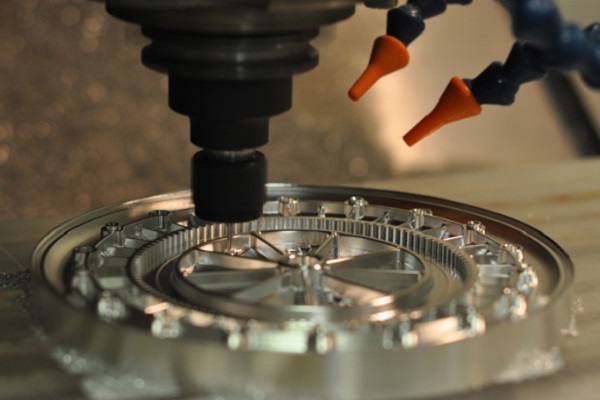

CNC precision machining process uses a computer with a special software installed and connected to a machine in order to automate the operation of the machine and eliminate the human intervention. CNC stands for Computer Numeric Control and it is one of those investments that can take your production business to the next level. This technology is expected to completely revolutionize the manufacturing industry, as well as the entire process of modern industry.

Before the CNC precision machining, every single machine in a production facility needed to be monitored and operated by a human. The completion of the monitoring and operation depended on the speed of the worker, but in general, it was a tedious and exhausting task that required the worker to closely watch the machines at all times while running. Today, CNC precision machining provides an incredibly precise measurements on any type of machine or job, for the production of any type of product.

The more axis the machine uses, the more accurate the results. Most commonly, CNC precision machines use 5 axis for best accuracy. A CNC machine with five axis offers an unlimited range of possibilities and it can create virtually anything you can imagine, including a human head replica. However, 2 or 3 axis of CNC machines is sufficient to create common industrial products, but if you need more complex products, with difficult angles or closets cuts, five axis machines are the best choice.

For the best results and to take full advantage of the CNC precision machining is to get your machine and software specifically designed for your application by a specialized CNC manufacturer. By working incredibly precise and fast, CNC precision machining speeds up your productivity and is able to re-produce large volumes with minimized probability of error. The number of finished products made from raw materials is greater. Since these are completely automatic and require a minimal human intervention, CNC precision machines can be left operating over long periods of time, including overnight.

Operators play an important role in the precision of these machines. To ensure proper operation of the CNC precision machining, you need to identify and set up the right tools for a particular job and place the material properly in the machine. As this software is designed in a special CNC technology code, one single mistake can impact the quality of the final product. For more accuracy, you must know the CNC technology and the behavior of the machine.

With the human error probability reduced to zero and by allowing business owners to save money on labour, it is safe to say that CNC precision machining is best solution for providing high-quality products to the customers.