Construction work is without a doubt difficult and gruelling. That means using every possible tool is a must because one relatively small mistake could mean the entire work going to waste. That’s a big reason why construction calculations are so time-consuming, as they’re one of the most important initial preparations to ensure the construction work goes on smoothly. That’s because, more often than not, people get bogged down in tiny details, such as nuts and bolts. That’s not to say these are professionals who do not know their field, but rather there are so many minuscule details to take care of, such as which bolts came into play. One of these types of bolts are the hold down bolts, or anchor bolts, and they are incredibly important.

Drop-in Anchor

This is one of the most used hold down bolts type in the industry, and it’s quite possible that it’s the first type of anchor bolt you’re going to encounter when shopping. Using them is relatively straightforward, as you insert a cork-screwed sheath into the mixture while the concrete is still wet. Once the mixture is fully dried, then you’ll have a port into which you can insert matching bolts. This type of hold down bolt is incredibly versatile, which is why it’s so commonly used. They see a lot of usage in the industry because of their simplicity, which is one of their strongest points.

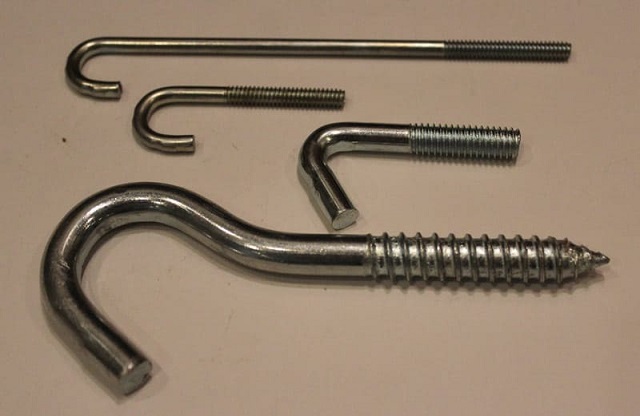

J-Bolt

It’s very easy to understand which type of anchor bolt the J-bolt is because it looks just like the letter J. To be more specific, these anchor bolts are actually elongated bolts that are hooked at one end, which is a design element that forms the shape of the letter J. The curved part of the bolt is sunk into wet concrete, which in turn allows for a nut to be screwed on the opposite part of the bolt. Once the nut is screwed onto the bolt, then the entire system will be significantly more secure.

L-Bolt

The L-bolt is actually quite similar to the J-bolt. However, unlike the J-bolt, the end of the bolt is not as curved, so instead of forming the letter J, this bolt forms the letter L. Similarly to the J-bolt, the L part of the bolt is sunk into a wet concrete slab. Because the J-bolt and the L-bolt are so similar, they are often used interchangeably in construction work, but they’re not exactly the same. Proper usage is necessary, so make sure to not confuse these two bolts because the end result might be less than satisfactory.

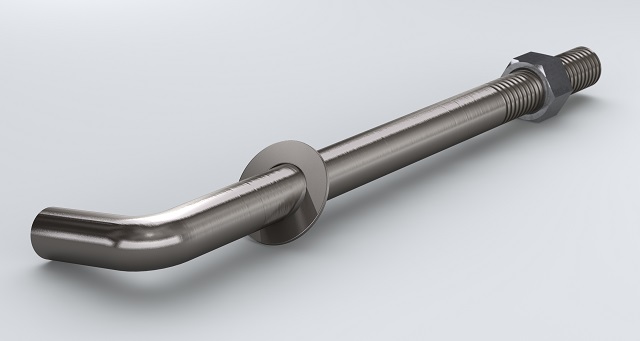

Plate Bolt

The main functionality behind the plate bolt is its versatility because it can take on a few different forms. These often include an attachment system that’s made up of a bolt shaped in the form of the letter T, which is typically mounted upside down in wet concrete. The T part of this bolt usually features a corkscrewed section on which you can mount, or weld, a nut and a circular plate. The plate bolt is one of the most used anchor bolts, so much so, they’re often considered the standard.

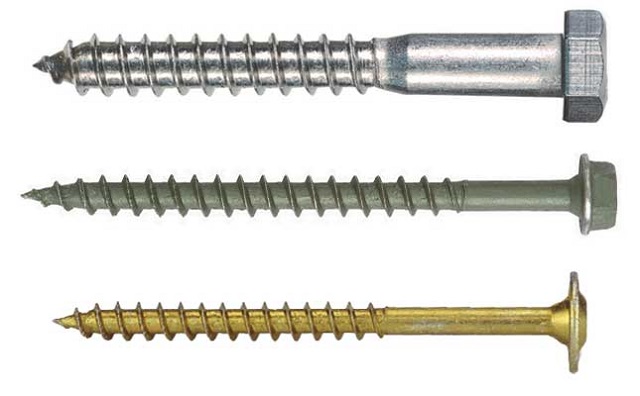

Lag Screw

This is a relatively straightforward type of anchor bolt. They’re sometimes referred to as shielded lag screws and are quite similar to plastic wall anchors that are used when you’re inserting screws into drywall. This is a mounting system that includes an expanding metal sheath when a lag screw is inserted. That means this type of anchor bolt is quite easy to install, so they’re frequently used in most industries.

Hammer Driver Pin

This is a type of anchor bolt that has a relatively unique look in that it appears like a specialty nail that’s used to mount thin materials onto concrete. Interestingly enough, this isn’t exactly far from the truth because these pins are best used to mount plywood onto concrete surfaces. The anchor part of the bolt is comprised of a skinny metal sheath, which is first inserted into the floor and then filled with a hammer driver pin. They are also installed quite quickly, making them a favourite to work with.

Toggle Wing

A lot of the time, construction work includes working with hollow walls, namely drywalls. In such cases, the toggle wing is arguably the best hold down bolt to work with. Essentially, the toggle wing is comprised of a long corkscrew bolt that features a hinged wing mechanism. Even though they’re combined, the whole is inserted through a pre-bored hole, with the idea that the toggle wing will expand after passing through it. The negative aspect of this anchor bolt is that it will not hold a very large amount of weight.

As evident, there is a large number of anchor bolts, or hold down bolts, to choose from. Most are significantly different, with only a few options being relatively simple, but the core principle is almost always the same. That means if you know which bolt you’re going to use, then actually using them will be quite simple. Just make sure to test them beforehand to know exactly how they’re used.