Metal contamination in your products is inconvenient, but it can also be a serious risk to your reputation, your equipment, and your bottom line. Whether you’re in food processing, recycling, mining, or manufacturing, even the smallest metal fragment can cause major issues. Fortunately, there’s a powerful solution built specifically to protect your operation.

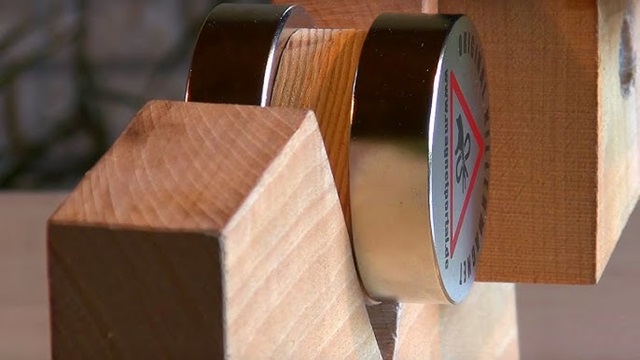

If you need reliable and efficient removal of ferrous contaminants, look for an adaptable and heavy-duty magnetic separator. It comes in various configurations to suit different applications, from conveyor systems to hoppers and chutes. They efficiently capture both large and fine metal particles, which helps reduce downtime, extend equipment life, and maintain high safety and quality standards. With user-friendly installation and minimal maintenance needs, they offer a practical and long-term solution to contamination control.

The Importance of Choosing the Right Device

Choosing the right magnetic separators for your operation is a critical part of protecting your product and your equipment. Not all systems are created equal, and using one that doesn’t match your industry’s needs can seriously backfire. Imagine trying to filter metal fragments from something as delicate as dairy with a unit designed for bulk grains. What works in one setup might not work in another, especially when hygiene standards vary so much between industries.

Using the wrong equipment can lead to missed contaminants, and that’s when things get expensive. A stray piece of metal that sneaks through could end up damaging downstream machinery, causing unexpected repairs and bringing production to a halt. And that’s not even touching on what a product recall or safety incident could mean for your brand. You need a solution that fits your materials, your process flow, and the demands of your workspace. When the stakes are high, it’s worth the time to find a system that’s truly built for the job, because the cost of cutting corners can go far beyond just dollars.

Buying Considerations

Every business has its unique demands, and finding a magnetic separator that fits well with your process can save you time, money, and headaches down the line. To get it right, there are several important things to think about.

First off, you want a tool that’s just right for how much product you handle. Too small, and it won’t keep up with your volume. Too big, and it might be a pain to install and unnecessarily expensive. Next up is the strength of the magnet itself. It needs to be powerful enough to catch even the tiniest metal bits, things like hardened steel shards or magnetic particles. Missing those can cause serious damage to your machinery or compromise product quality.

Another big consideration is how fast your product moves through the system. Look for a magnetic separator for sale that keeps up with your production line’s speed without slowing things down or causing blockages. Some require manual cleaning, which can be a chore, while others come with automatic cleaning features that save time and reduce labour.

You’ll also want to think about the product itself. Is it dry, wet, sticky, or abrasive? The right equipment will handle your product’s specific nature without losing effectiveness. Placement matters too; whether you need it near the start, in the middle, or at the end of your line can influence which option is best. Lastly, check that everything meets the necessary safety and hygiene standards for your industry, especially if you’re in food, pharma, or dairy.

To sum it up, here’s what you should keep in mind when buying a magnetic separator in Australia:

- Match the size to your production volume and space;

- Ensure magnetic strength suits the contamination risk;

- Choose a unit that can handle your flow rate smoothly;

- Consider how easy and efficient the cleaning process is;

- Pick equipment designed for your product’s specific traits;

- Think about where in your line it will be installed;

- Verify compliance with industry regulations and hygiene standards.

Industry Applications

Where are magnetic separators used? When it comes to keeping metal contamination at bay, different industries have unique challenges, so the right device needs to match the job perfectly:

- In pet food production, for example, purity is everything. Metal bits can sneak in from raw materials or worn-down machinery parts, and if your equipment isn’t up to scratch, those tiny fragments can make it into the final product. That’s a big problem because it risks animals’ health and could mean costly recalls. So, having a separator designed specifically for this industry helps keep things safe and compliant;

- Meat rendering is another tough one. The materials processed here are rough and abrasive, so the equipment should be sturdy. If the separator isn’t built to handle this, metal pieces might get missed, which can ruin product quality or even cause damage to your machines. A heavy-duty, reliable system keeps everything running smoothly;

- Then there’s the bakery industry, where metal contamination can happen at lots of different points, whether it’s during ingredient delivery, mixing, dough proofing, or even packaging. If metal fragments sneak through, it can hurt customer trust and your brand’s reputation. So, choosing a separator that works well in a busy, fast-paced bakery environment is crucial to catch any contaminants before they reach the consumer.