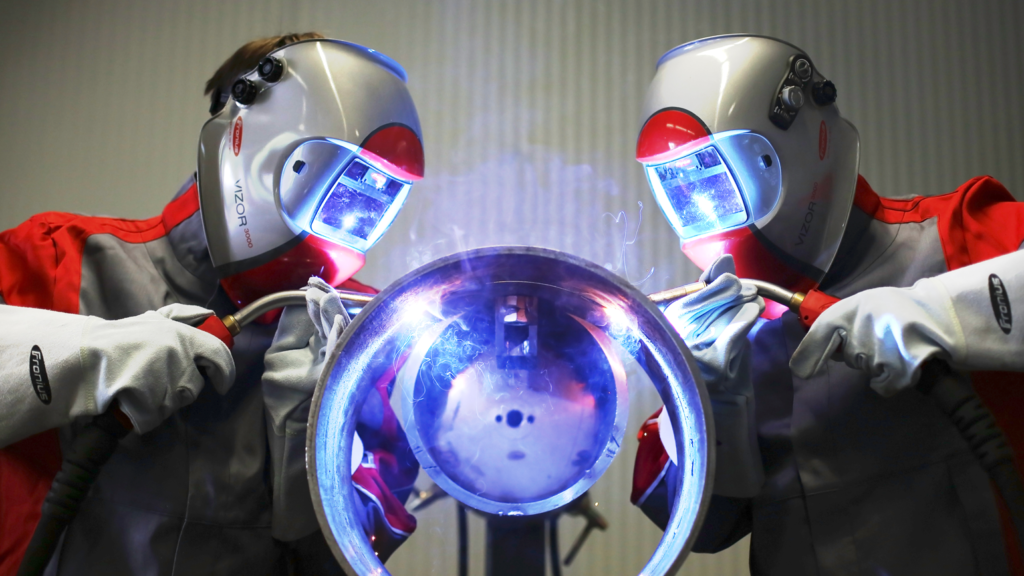

Safety is one of the most important things to consider when working on construction sites, or in manufacturing jobs. Although every work environment can be a potential threat to safety, welding from the get-go is a dangerous profession. The gas and fumes that are released during welding can be toxic, and it’s not uncommon to see welders wearing masks so they don’t inhale those harmful substances. This is because you’re dealing with hazardous materials and equipment that can cause serious injury if not handled properly.

One way to make sure you are protected while completing these tasks is by investing in protective gear. Each protective garment is made to withstand both the elements and work impact. They add a layer of safety to your body, but even with the proper equipment, there is still a risk of injury or death from the heat of the metal as it melts. That’s why auto-darkening welding helmets are essential gear for any welder who wants to do their job safely!

These helmets will protect your face from the intense light emitted during welding and provide a clear view of what you are doing without having to take them off constantly. They also come with safety goggles that block out ultraviolet rays, so they can be used indoors or outdoors too!

Protective Welding Helmets

A welding helmet is an essential piece of safety equipment for any construction worker, welder, or manufacturer. When working in such a high-risk industry, having proper protection is a crucial investment that can lower your chances of injury and potentially save your life. The market offers you an extensive selection of various protective garments, but the first and most essential one is a welding helmet.

Currently, you can find two types of welding helmets and they each serve a different purpose. So let’s go more into detail about protecting yourself and still doing the job right!

Auto-Darkening Helmet

It’s no surprise that welding helmets auto darkening have become the most popular type of welding helmet over the last decade. They’re a huge advancement in safety, and they’re much more affordable than they were just a few years ago.

The welding helmets auto darkening protect the eyes from intense light and harmful UV rays. It also offers arcs with 14 shades to filter out high-intensity light before it reaches your eyes, which can cause damage to the retina. These helmets are designed with an auto-darkening feature that switches from dark lenses to clear lenses as soon as they detect bright light sources such as flames, sparks, and explosions. They protect you from hazardous situations by providing maximum visibility in all lighting conditions while allowing you to see at night without shining a flashlight on what you’re working on.

This helmet offers a number of features that make it easy to weld. The lenses are designed to adjust to head positions and light, so you won’t have to stop every time you need to change a lighting filter. In addition, these helmets come with special padding that is both soft at touch and breathable, so the heat won’t affect you while working. The material of darkening helmets is sturdy enough to endure impact, yet also comfortable enough to give adequate support to your neck and spine.

Although auto-darkening helmets fall on the more expensive side, they have a longer life span than regular helmets, which means you won’t have to replace the lens every few weeks.

Passive Welding Helmets

Passive welding helmets are the standard type of welding helmet, providing protection from radiant energy and excessive light. They feature a shade that slides up or down to protect your eyes from hazardous levels of ultraviolet rays. The design features an adjustable headband made out of leather for maximum comfort.

This type of welding helmet is used in a less hazardous situation and is the most common one. Passive welding helmets include lenses that provide a level 10 shade, which essentially does the job. These helmets can sometimes seem like a hassle, as you’d need to constantly slide them up and down during welding to check on the process. But for their low prices, they are fit enough to protect you. Plus, replacement of the lens is pretty cheap, so that won’t put a dent in your budget.

The Benefits of Welding Helmets

Welding requires intense concentration on the task at hand, which can cause problems if not wearing proper safety gear. A welding helmet protects against dangerous ultraviolet rays that could otherwise harm your eyes, but the benefits don’t stop there. Apart from the obvious ones, using this helmet improves your life by:

•

- Protecting your face and skin from sparks and heat from the metals

- Preventing eye strain and cataracts

- Blocking out UV rays, which cause skin cancer

- Filtering out hazardous chemicals that are released when welding

- Preventing metal pieces from flying at your head

- Elevating productivity levels

- Providing support to your spine and neck while welding

Safety Tips for Welding

Welding safety is one of the most important aspects of welding, and it should be a priority for all welders. Welding safety can be tricky because you are dealing with such high temperatures that will burn your skin in seconds if you’re not careful. However, there are many safety tips that you can follow to ensure that you stay safe when working with metal in such intense heat.

First and foremost, you need to wear the proper attire and accessories for welding. This includes everything from helmets and goggles to heat-resistant suits. One spark can lead to lifelong scars or even life-threatening injuries, so investing in protective gear and being extra careful will guarantee a productive welding experience.

Next, you need to know how to handle the welding equipment. Whether you’re a new or experienced welder, practice and extensive knowledge will help you wield the machines and give you an upper hand in case things go astray. When entering this industry, you have to be prepared for any scenario.

Another great safety tip is to always work in a safe and controlled environment. This means having enough space to operate the equipment, quality ventilation to air out the toxic fumes and having fire-extinguishers close by at any given moment. Before you even start welding, make sure to remove any flammable materials. Welding seems like an intimidating profession but once you’ve gotten the hang of it and safety protocols, you will quickly excel and master the craft.